|

|

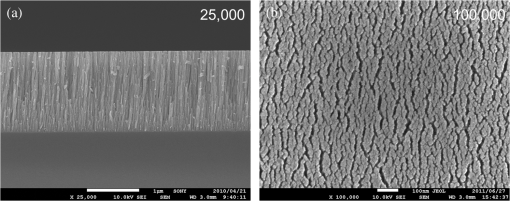

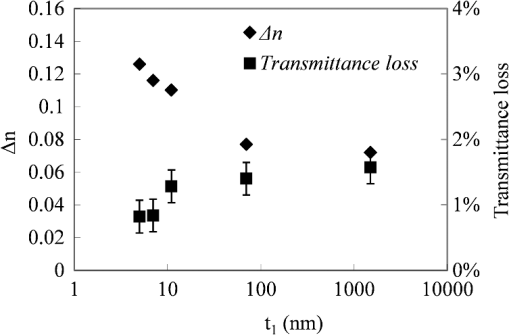

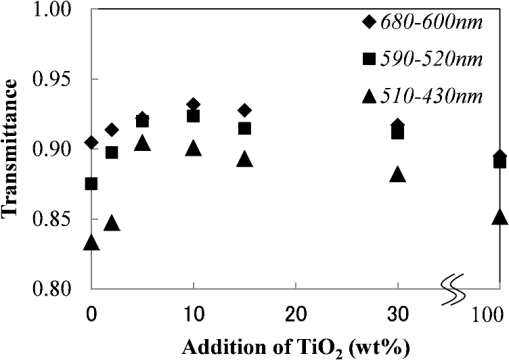

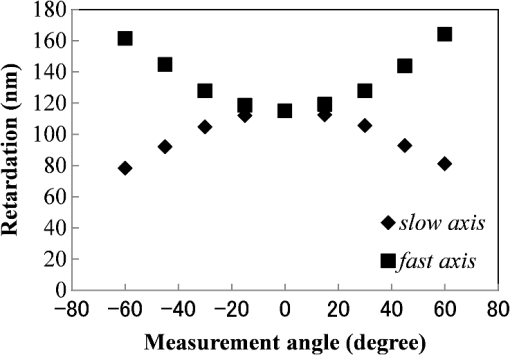

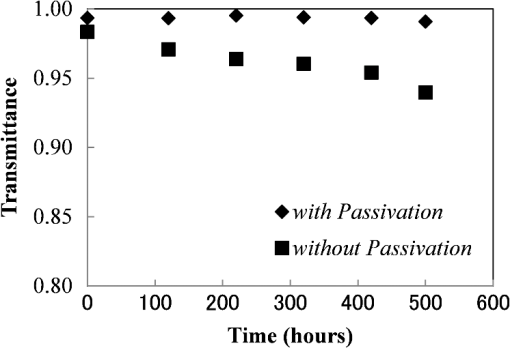

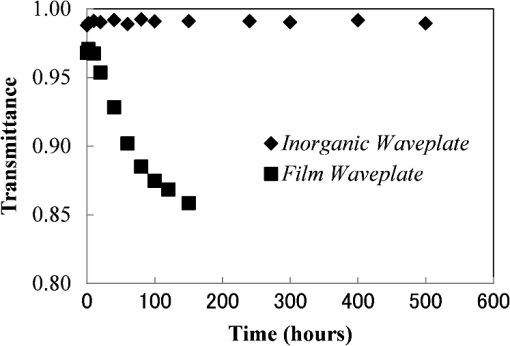

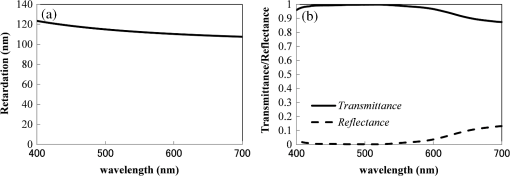

1.IntroductionThe demand for optical devices with high-light resistance and thermal durability is increasing because requirements such as increased luminescence and miniaturization of liquid crystal display (LCD) projectors. Polymer-based wave plates are widely used in LCD projectors. They contain organic materials that degrade easily under long, intense exposure to light from a superhigh-pressure mercury lamp. Therefore, wave plates of inorganic materials with high-light resistance and high-thermal durability are required for those applications. It is well known that obliquely deposited thin films can be applied to wave plates.1–4 The oblique deposition can lead to the formation of birefringent layers on any substrate at low cost without size limitation. Because these wave plates are composed of inorganic materials, superior thermal durability is expected. High transmittance and exact control of retardation value are extremely important for using wave plates with obliquely deposited films in practical optical instruments. Several researchers have reported solutions2,4 for improving the transmittance, which depends on the smaller birefringent, , and, occasionally, on film haze.1 Several studies have reported that the retardation films prepared by the serial bideposition technique4–6 have nanostructural growth perpendicular to the substrate, and can therefore be used for increasing . Film thickness could decrease at high values of . Moreover, Motohiro et al.2 suggested that the columnar growth normal to the substrate can reduce polarization-dependent reflection, which occurs owing to the interface of bilayered retardation films1 and is obstructive in some applications.7 Meanwhile, Motohiro and Taga1 explained that the nature of haze can be attributed to agglutination of the columns; therefore, if columnar structures are considerably smaller than the wavelength of light, the resulting haze value is very low. Serial bideposition films consist of numerous individual thin layers. Hence, it is possible that haze can be reduced by inhibiting column agglutination. However, there have been few reports on the relationship between the birefringent and the transmittance of serial bideposition films. In addition, we noticed the effect of the composition of serial bideposition films on their optical properties. The birefringence values of several materials’ oblique deposition films were reported,1,4 and large were obtained for , , ZrO, and when deposited at lower temperatures. Furthermore, Motohiro and Taga mentioned that obliquely deposited films show high transmittance in the visible spectrum range.1 In contrast, there have been few attempts to investigate the effect of element addition on the optical properties of obliquely deposited film. Several studies reported that the addition of to thin films prepared by chemical vapor deposition8 or radio frequency magnetron sputtering deposition9 can improve the films’ insulating properties. It is considered that this improvement occurs owing to the compensation of oxygen vacancies8 contained in films evaporated at lower temperatures.10–13 We consider that this result implies the addition of to films could improve the films’ transmittance by compensating for oxygen vacancies with serial bideposition films. In this paper, we present the microstructures and optical properties of serial bideposition films. Then, we clarify the effect of with additive. Finally, to verify the advantages of the above configuration, we demonstrate an inorganic quarter wave plate with high transmittance, thermal durability, and light resistance. The novelty of this paper is in production of very practical inorganic wave plates prepared by the serial bideposition technique. 2.ExperimentsSerial bideposition films of () were formed on a glass substrate with an EB source placed at a source-to-substrate distance of 1000 mm under a pressure of . During evaporation, deposition angle, , measured from the surface normal, was fixed to 70 deg, while the azimuth was rapidly switched by 180 deg with each deposition of a 5–1600-nm-thick layer, . Serial bideposition films with a total thickness, , of 800–1600 nm were prepared by repeating 0–200 cycles of each deposition, and subsequently annealing at 200°C in air. Passivation layers of and antireflection coatings of are formed on the serial bideposition films using a magnetron sputtering system. Microstructures and compositions of serial bideposition films were investigated by scanning electron microscopy (SEM) and energy dispersive -ray spectrometry, respectively. The transmittance and reflectance were measured using a double-beam spectrophotometer in the wavelength range of 400–700 nm with polarized light. For reflectance measurements, the angle of incidence of light was 5 deg, and the spectra of specularly reflected light were acquired. In contrast, transmittance spectra were measured for normal incidence. Diffuse scattering in the off-specular or off-normal directions was negligible. The birefringence was evaluated using a phase-retardation measurement system with a rotating analyzer. Humidity resistance was evaluated by measuring the transmittance of the serial bideposition films, which were maintained at 60°C and 90% R.H for different storage times and then maintained at 23°C for 24 h. Light resistance properties were evaluated by measuring the transmittance of serial bideposition films irradiated with a light intensity of from a high-pressure mercury lamp for different storage times and then maintained at 23°C for 24 h. 3.Results and Discussions3.1.MicrostructuresFigure 1 shows the morphology of the serial bideposition () film for and . Figures 1(a) and 1(b) show the SEM images of the cross-sectional views parallel to the deposition plane of the flux and the top view, respectively. It is observed that the serial bideposition film is composed of narrow, long, columnar structures, and that many bundles and gaps derived from the columnar structures were along the normal to the flux deposition plane. This surface morphology can be observed even on a film prepared by conventional oblique deposition. In the case of serial bideposition, the shadowing area lies alternately in front of and behind the columns, and, accordingly, the intercolumn gaps are widened, and bundles are formed more visibly.6 Therefore, the degree of anisotropy of the surface morphology is considerably higher than that of a conventional obliquely deposited film. 3.2.Optical PropertiesThe birefringence and transmittance loss of the () serial bideposition film at the wavelength of 550 nm as a function of thickness with are shown in Fig. 2, in which the plot of is equivalent to the film prepared by conventional oblique deposition. Transmittance loss was calculated by subtracting the sum of transmittance and reflectance from 100%. As for the birefringence, increases with decreasing when is less than 70 nm, whereas it remains same as that of the conventional oblique deposition film when is more than 70 nm. With serial bideposition, Hodgkinson and Wu4 explained that structural growth occurs in plate-like columns perpendicular to both the deposition plane and the substrate when individual layers are thin. In the case of such a structure, Hodgkinson et al. estimated a 100% increase in for a packing density using equation for form birefringence.14 This value coincides with an increase in the of serial bideposition () films, as shown in Fig. 1. In our case, it is considered that the plate-like columns grow when is less than 10 nm. The transmittance loss is the least at around , and it seems to be unchanged for . For , agglutination of the columnar structures of a stack of individual thin layers whose directions alternate could be prevented, thus reducing haze. Moreover, it is considered that the narrow, long columns standing normal to the substrate instead of being inclined, as with conventional oblique deposition, reduced the amount of light reflected off the interface. As the result, the transmittance loss is decreased because . The transmittance loss for both orthogonal polarizations is decreased. This result shows that the serial bideposition films can not only achieve larger but also decrease the transmittance loss compared with conventional obliquely deposited films. 3.3.Influence of TiO2 AdditionThe optical transmittance of () serial bideposition films as a function of composition is shown in Fig. 3, in which the rhombuses, squares, and triangles indicate the transmittance averaged over the wavelength ranges of 680–600, 590–520, and 510–430 nm, respectively. Thickness values of and were selected so that the influence of additive on transmittance could be recognized easily. As seen in the figure, the transmittance is maximized at and decreases at both and ; particularly, the transmittance is improved in the wavelength range of 51–430 nm at , respectively. Saitoh et al. revealed that a low concentration of doping in a film by chemical vapor deposition could reduce the leakage current of the film.8 In that case, they explained that oxygen vacancies are possibly compensated for by ions, which are substitutionally incorporated into sites in the film.8 This suggests that the transmittance improvement of serial bideposition films at lower doses is due to a decrease in the number of oxygen vacancies in the . Although the exact mechanism responsible for this improvement is yet to be found and we need further experiments to reveal the same, it is considered that adding a small amount of to can reduce the resulting film’s transmittance loss. The serial bideposition film with a lower dose of in is potentially applicable to wave plates in applications requiring high transmittance. 3.4.Properties of Wave Plate ApplicationFigures 4(a) and 4(b) show the retardation and transmittance/reflectance spectra of () serial bideposition films with antireflection coatings for and . The retardation of 115 nm at , which corresponds to a quarter wave plate for the wavelength, is achieved. In the wavelength range of 430–510 nm, the transmittance and reflectance averaged over were more than 99% and less than 0.5%, respectively. Fig. 4(a) Retardation and (b) Transmittance/reflectance spectra of () serial bideposition film with antireflection coating for and .  Figure 5 shows the angle dependence of the retardation of a serial bideposition film at . Rotation around the fast axis increases the retardation, whereas rotation around the slow axis decreases the retardation. In addition, angle dependence is symmetrical about 0 deg. In the case of conventional obliquely deposited films, angle dependence is asymmetric around 0 deg.1,3 In the case of a serial bideposition film, angle dependence is symmetric because narrow, long columnar structures perpendicular to the substrate are formed, as shown in Fig. 1(b). This angle dependence of serial bideposition films corresponds to the homogeneous biaxial indicatrix. Although serial bideposition films are composed of numerous individual thin layers, they can be considered as a homogeneous single layer with an optical axis parallel to the substrate because each layer of the stack has a thickness that is a fraction of the operating wavelength. This result offers the following advantage. Optical devices are preferred to have left-right symmetric optical properties when they are used for optical instrument using luminance fluxes that have a definite incidence angle such as LCD projectors. Asymmetric optical properties lead to uneven luminance, and hence, the quality of the projected image deteriorates. Therefore, serial bideposition films with symmetric properties are applicable to wave plates mounted inside actual optical instruments. 3.5.Wave Plate ReliabilityFigure 6 shows the change in the averaged transmittances of serial bideposition films with or without the passivation layer at a temperature of 60 °C and relative humidity of 90% (i.e., humidity resistance test). The transmittance decreases monotonically with time without the passivation layer and is lowered by 20% after 500 h, whereas it remains unchanged with the passivation layer. Figure 7 shows changes in the transmittance with time under irradiation from a light intensity of (i.e., light resistance test). For comparison, a conventional organic wave plate was tested as well. Our inorganic wave plate with a serial bideposition film showed significant/superior robustness to irradiation, and there was no degradation in its optical characteristics or appearance. Conversely, the transmittance of the organic wave plate deteriorated rapidly, and it finally burned out after 200 h of irradiation. As a result, it is shown that our fully inorganic wave plates with a serial bideposition film is advantageous for applications in which it is used under either/both high-humidity or high-power light irradiation. 4.ConclusionWe investigated the optical characteristics and microstructures of serial bideposition () films. The dense, narrow, and long columns that grow quasiperpendicular to the substrate give rise to higher birefringence and lower transmittance loss compared with conventional obliquely deposited films. Additionally, we investigated the effect of addition to . It was found that a small amount of additive can improve the film’s optical transmittance, especially at shorter wavelengths. We demonstrated a fully inorganic quarter wave plate with the serial bideposition film of (), which achieved both high transmittance and low reflectance at , as well as symmetric angle dependence of retardation. Finally, we showed the superior durability of our wave plate under both high-humidity and high-power light irradiations. It is expected that the developed wave plates can be applied to applications requiring high transmittance and long-term operation stability under high temperatures. AcknowledgmentsThe evaluation of optical properties and microstructures presented in this manuscript was performed by Nobuyuki Koike. The fabrication of wave plates and relativity experiments was performed by Nobuyuki Koike and Koji Sasaki. Naoki Hanashima and Takatoshi Yamada worked on data analysis. Akio Takada and Motofumi Suzuki provided the valuable suggestion and discussion through the entire process of the research. ReferencesT. MotohiroY. Taga,

“Thin film retardation plate by oblique deposition,”

Appl. Opt., 28

(13), 2466

–2482

(1989). http://dx.doi.org/10.1364/AO.28.002466 APOPAI 0003-6935 Google Scholar

T. Motohiroet al.,

“Simultaneous oblique deposition from opposite azimuthal directions for fabrication of thin film retardation plates,”

Proc. SPIE., 2873 214

–217

(1996). http://dx.doi.org/10.1117/12.246223 PSISDG 0277-786X Google Scholar

I. HodgkinsonQ. H. Wu,

“Practical designs for thin film wave plates,”

Opt. Eng., 37

(9), 2630

–2633

(1998). http://dx.doi.org/10.1117/1.601763 OPEGAR 0091-3286 Google Scholar

I. HodgkinsonQ. H. Wu,

“Serial bideposition of anisotropic thin films with enhanced linear birefringence,”

Appl. Opt., 38

(16), 3621

–3625

(1999). http://dx.doi.org/10.1364/AO.38.003621 APOPAI 0003-6935 Google Scholar

M. SuzukiY. Taga,

“Integrated sculptured thin films,”

Jpn. J. Appl. Phys., 40

(Part 2, No. 4A), L358

–L359

(2001). http://dx.doi.org/10.1143/JJAP.40.L358 JJAPA5 0021-4922 Google Scholar

M. Suzukiet al.,

“Au nanorod arrays tailored for surface-enhanced Raman spectroscopy,”

Anal. Sci., 23

(07), 829

–833

(2007). http://dx.doi.org/10.2116/analsci.23.829 ANSCEN 0910-6340 Google Scholar

A. LakhtakiaR. Messier,

“Reflection at the Motohiro–Taga interface of two anisotropic materials with columnar microstructures,”

Opt. Eng., 33

(8), 2529

–2534

(1994). http://dx.doi.org/10.1117/12.177108 OPEGAR 0091-3286 Google Scholar

M. SaitohT. MoriH. Tamura,

“Electrical properties of thin films grown by chemical vapor deposition,”

Int. Electron. Devices Meet. Tech. Dig., 86

(Session 29), 680

–683

(1986). http://dx.doi.org/10.1109/IEDM.1986.191283 TDIMD5 0163-1918 Google Scholar

J.-Y. GanY. C. ChangT. B. Wu,

“Dielectric property of thin films,”

Appl. Phys. Lett., 72

(03), 332

–334

(1998). http://dx.doi.org/10.1063/1.120746 APPLAB 0003-6951 Google Scholar

C. HashimotoH. OikawaN. Honma,

“Leakage-current reduction in thin films for high-density VLSI memories,”

IEEE Trans. Electron. Dev., 36

(01), 14

–18

(1989). http://dx.doi.org/10.1109/16.21171 IETDAI 0018-9383 Google Scholar

M. Matsuiet al.,

“Amorphous silicon thin-film transistors employing photoprocessed tantalum oxide films as gate insulators,”

Jpn. J. Appl. Phys., 29

(Part 1, No. 1), 62

–66

(1990). http://dx.doi.org/10.1143/JJAP.29.62 JJAPA5 0021-4922 Google Scholar

U. TeravaninthornY. MiyaharaT. Moriizumi,

“Influence of reactive gas pressure on the properties of thin-film ,”

Jpn. J. Appl. Phys., 26

(03), 347

–351

(1987). http://dx.doi.org/10.1143/JJAP.26.347 JJAPA5 0021-4922 Google Scholar

S. Banerjeeet al.,

“Conduction mechanisms in sputtered on Si with an interfacial layer,”

J. Appl. Phys., 65

(03), 1140

–1146

(1989). http://dx.doi.org/10.1063/1.343052 JAPIAU 0021-8979 Google Scholar

I. HodgkinsonQ. H. Wu, Birefringent Thin Films and Polarizing Elements, World Scientific, Singapore

(1997). Google Scholar

BiographyNobuyuki Koike has been working on the development of inorganic devices with submicron structures in Dexerials Corporation, Japan. Koji Sasaki has been working on the development of inorganic devices with submicron structures in Dexerials Corporation, Japan. Takatoshi Yamada has been working on the development of inorganic devices with submicron structures in Dexerials Corporation, Japan. Naoki Hanashima has been working on the development of inorganic devices with submicron structures in Dexerials Corporation, Japan. |